Since the beginning of the 21st century, with the rapid development of science and technology, online shopping in e-commerce has been in a state of rapid growth for many years, and the global epidemic of COVID-19 has intensified this growth. E-commerce sales in 2021 are 44% higher than in 2010. While the retail warehousing operation is highly automated, the demand for autonomous mobile robots and Automatic Guided Vehicles (AGVs) is also increasing. Autonomous mobile robots and autonomous navigation vehicles run around the clock and are responsible for carrying out dangerous activities and repetitive tasks carried out manually in the past. Online retailing will continue to grow, driving demand for smarter and more powerful autonomous mobile robots.

In order to realize the wireless smart operation technology of storage robot, the machine must have strong vision (camera + lidar), strong processing power (low power consumption and high performance processor) and strong interface expansion ability.

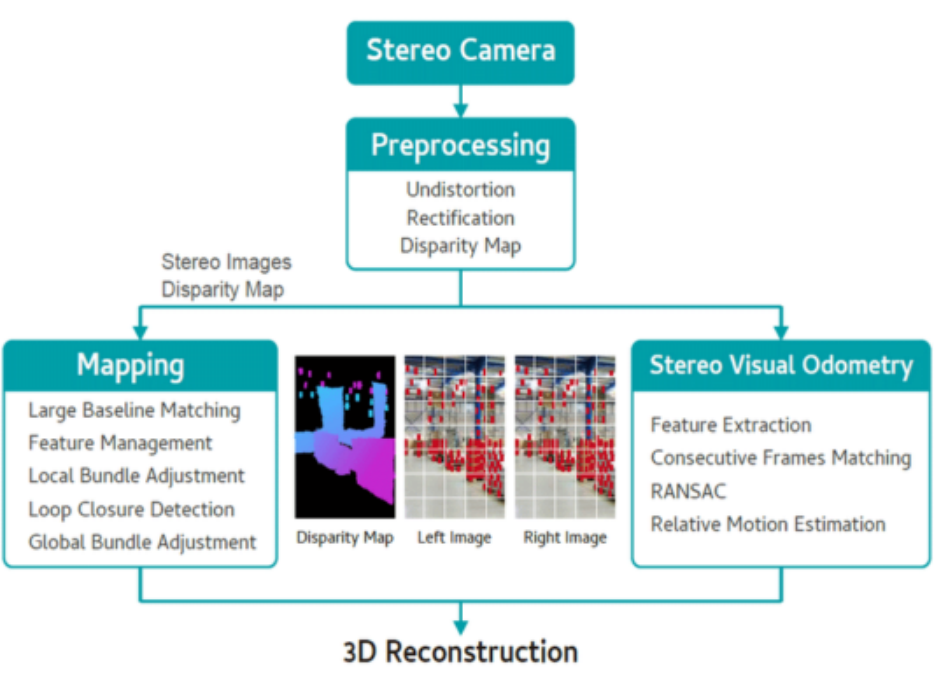

The machine vision stereoscopic camera is used to generate real-time video about the surrounding environment to generate a parallax map used to calculate the position and depth of the object in the physical space. Reconstruct the 3D map of the environment for path planning / navigation, obstacle identification, avoidance, etc.

When starting autonomous mobile robot projects, mobile robot manufacturers need controllers that can support high reliability and long life cycle, multiple sensor interfaces (including unusual industrial interfaces such as CAN RS-485), and no loss of performance under high vibration and signal interference. Embedded computers are very popular because of their advantages in power consumption, performance and reliability.

In order to meet the business needs of artificial intelligence warehousing robots, ANOVO CO., LTD. launched the Quark 100H series, using the sixth and seventh generation Intel? Core? processors as the basis for building the Quark 100H series, which enables our controllers to improve performance by up to 50% compared with previous generations.

Multi-CPU cores, integrated Intel? HD Graphics 520 cores, and new media features of the Core? processor:

● Manage 2D and 3D camera and scanner arrays.

● Perform imaging, neural network and mapping workloads according to visual and navigation needs.

● Assist in redirecting to the required control tasks.

● The main operating system running autonomous mobile robots.

At the same time, the processor energy efficiency (its thermal design power [TDP] is as low as 15W and the lowest configurable is 7.5W) also has significant design advantages in terms of system size and reliability. Low power consumption has a direct impact on battery life, but it also means that the platform requires less heat dissipation. The size of the chassis is 80% smaller than that of the traditional IPC, while still operating in a wide temperature range of-20 ℃ to 60 ℃。