With the advent of Industrial 4.0 era, machine vision plays a more and more important role in the field of smart manufacturing. Machine vision uses robots instead of human eyes to measure and judge, which is a technology that applies image processing to non-contact detection and measurement in the field of industrial automation, improves machining accuracy, finds product defects, and makes automatic analysis and decision-making. In addition, it is also an important part of advanced manufacturing industry and plays an irreplaceable role.

In recent years, industrial computer technology has developed rapidly. Relying on the strong support of industrial computers, machine vision technology is more and more applied to the on-line inspection of industrial production to achieve rapid and complete inspection of product quality without omission, so as to achieve zero defect of product quality. At present, machine vision is mainly used in surface quality inspection, size measurement, target positioning, target recognition, target ratio equivalence, the fields involved include iron and steel, non-ferrous metals, plastics, glass, textile, papermaking, electronics, precision parts, etc.

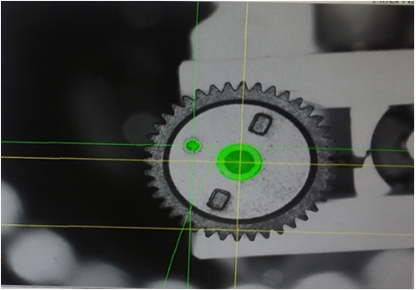

The machine vision inspection system uses a CCD camera to convert the detected target into an image signal, which is transmitted to a special image processing system. The system is transformed into a digital signal according to pixel distribution, brightness, color and other information. The image processing system carries out various operations on these signals to extract the features of the target, such as area, quantity, position, length, and then output the results according to the preset permissible degree and other conditions. including size, angle, number, qualified / unqualified, with / without, etc., to achieve automatic recognition function.

Product advantages:

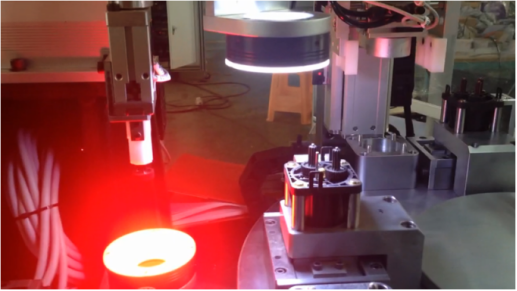

1. The powered POE can provide light source lighting for machine vision.

2. Powerful CPU processing provides the operation after computer comparison.

3. PPC15 provides interchangeable CPU and highly dynamic design, allowing customers to tailor to their own preferences.

4. With a compact 4-inch circuit board, PPC15 can produce maximum performance in the ever-changing environment of industrial 4.0. .

5. PPC15 commercially supports most major operating systems and is compatible with the 9x24V power supply. The backlight inverter power supply can reach up to 12V.

Machine vision, smart vision and image technology are the important core of Industrial 4.0. Mutual promotion of development is not only the necessity of technology, but also the choice of the times. Anovo · China North strives to develop core competencies, strengthen innovation, and join forces with automation equipment manufacturers and robot manufacturers to "implant eyes and brains into machines" to make visual imaging technology the backbone and carry the banner of upgrading the manufacturing industry! We take the initiative to shoulder the historical mission of helping China's industrial manufacturing industry to transform and upgrade, work hard and lead the future.